Microscopical reasons for crack propagation

Subject area:

Nanomechanics

Responsible employees:

Prof. Dr. rer. nat. Mathias Göken

Prof. Dr. Benoit Merle

Prof. Dr.-Ing. Erik Bitzek (Privatdozent)

Stefan Gabel (M.Sc.)

Cracks are crucial for the strength of a material. A classic assumption would be that a component half the size can only carry half the load. But a crack that goes halfway through a component reduces this bearable load to a fraction of this. Due to its sharp and pointed geometry, the crack creates excessive stresses on its front, which causes the material to fail at the crack tip. This failure continues through the entire component and leads to failure. Brittle materials are therefore massively weakened even by microscopic cracks, whereas ductile materials dull the crack.

Metals, which have a so-called body-centered cubic structure, such as iron, tungsten, chromium, etc., have a special position. At low temperatures, they suddenly become brittle, as the mechanism for blunting the cracks is suppressed by the low mobility of the atoms. However, this critical temperature can be shifted by various effects such as the purity of the material, pre-deformation or beam damage.

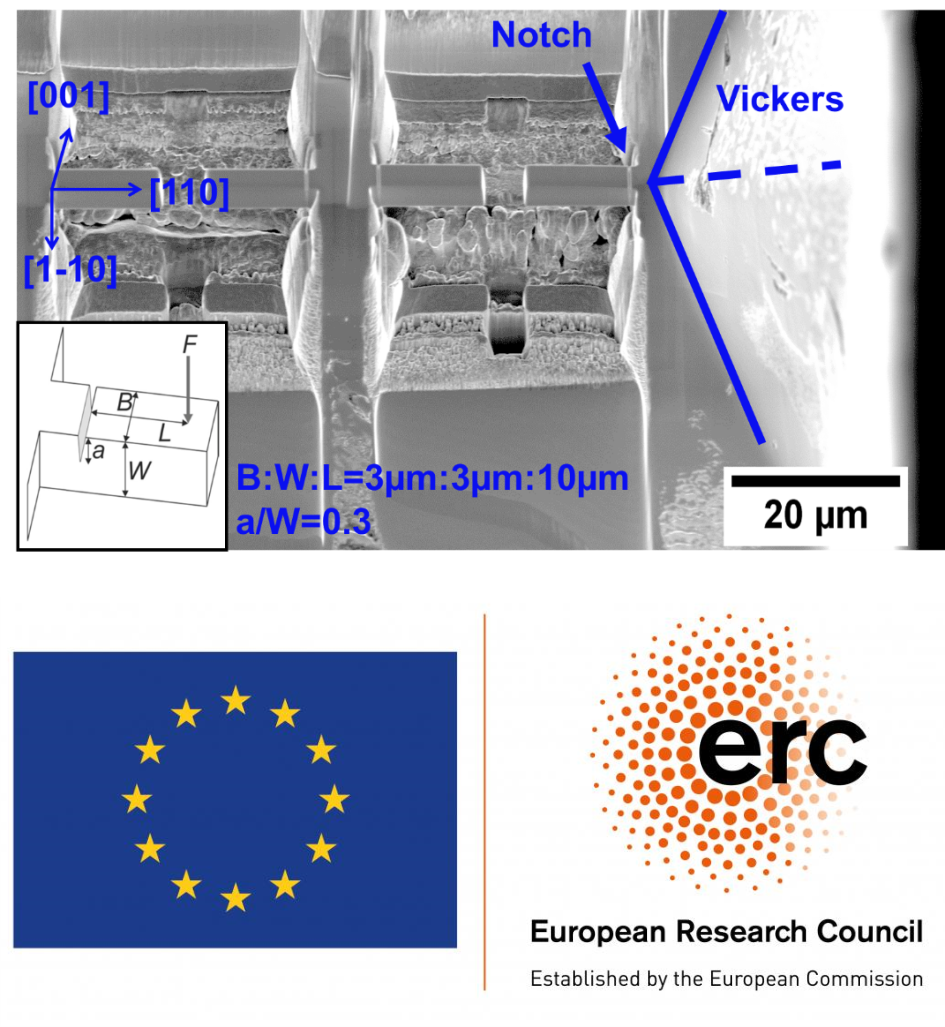

The aim of the project is to use micromechanical investigation methods such as bending microbeams, cryogenic nanoindentation and transmission electron microscopy to investigate the influence of the effects mentioned on the deformability at crack tips and to develop a simulation model for body-centered cubic structures using the underlying mechanisms.

This project is part of a project for which funding from the European Research Council (ERC) was made available within the framework of the European Union’s programme for research and innovation “Horizon 2020”. (microKIc – Microscopic Origins of Fracture Toughness; PI: Erik Bitzek)