Filament 3D printer

Filament 3D Printer

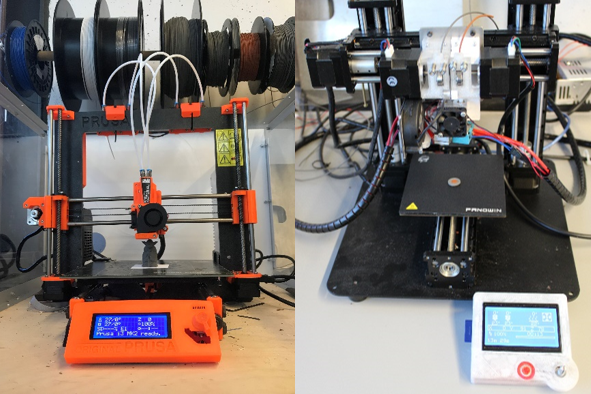

Prusa i3 MK2 with multi-material upgrade for filament 3D printing of conventional FFF filaments. It is used in research for 3D printing of highly filled filaments with proportions of 55-60 vol% metallic or ceramic powders.

Specifications

- Build volume: 250 x 210 x 210 mm

- Filament diameter: 1.75 mm

- Nozzle diameter: 0.4 mm; 0.6 mm; 0.8 mm

- Max. Print speed: 200 mm / s

- Minimum layer height: 0.05 mm

- Heated build platform

- Automatic print bed leveling

The Panowin F1 printer has a custom-built 2-nozzle-upgrade to allow dual extrusion of different materials. It is used in research for 3D printing of composites and complex components with proportions of 55-60 vol% metallic powders.

Specifications

- Build volume: 120 * 125 * 125 mm

- Filament diameter: 1.75 mm

- Nozzle diameter: 0.4 mm; 0.6 mm; 0.8 mm

- Max. Print speed: 120 mm / s

- Minimum layer height: 0.05 mm

- Heated build platform

- Dual extruder system

Available materials

- PLA

- ABS

- PETG

- Stainless Steel (1.4404)

- Titanium

- Copper

- IN 718

- Alumina

Responsible employees:

Department of Materials Science and EngineeringProf. Dr. Peter Felfer

Chair of General Materials Properties