Micro- and nanomechanical characterization of superalloys at elevated temperatures

Subject area:

High Temperature Materials

Responsible Employees:

PD Dr. Steffen Neumeier

Lukas Haussmann (M. Sc.)

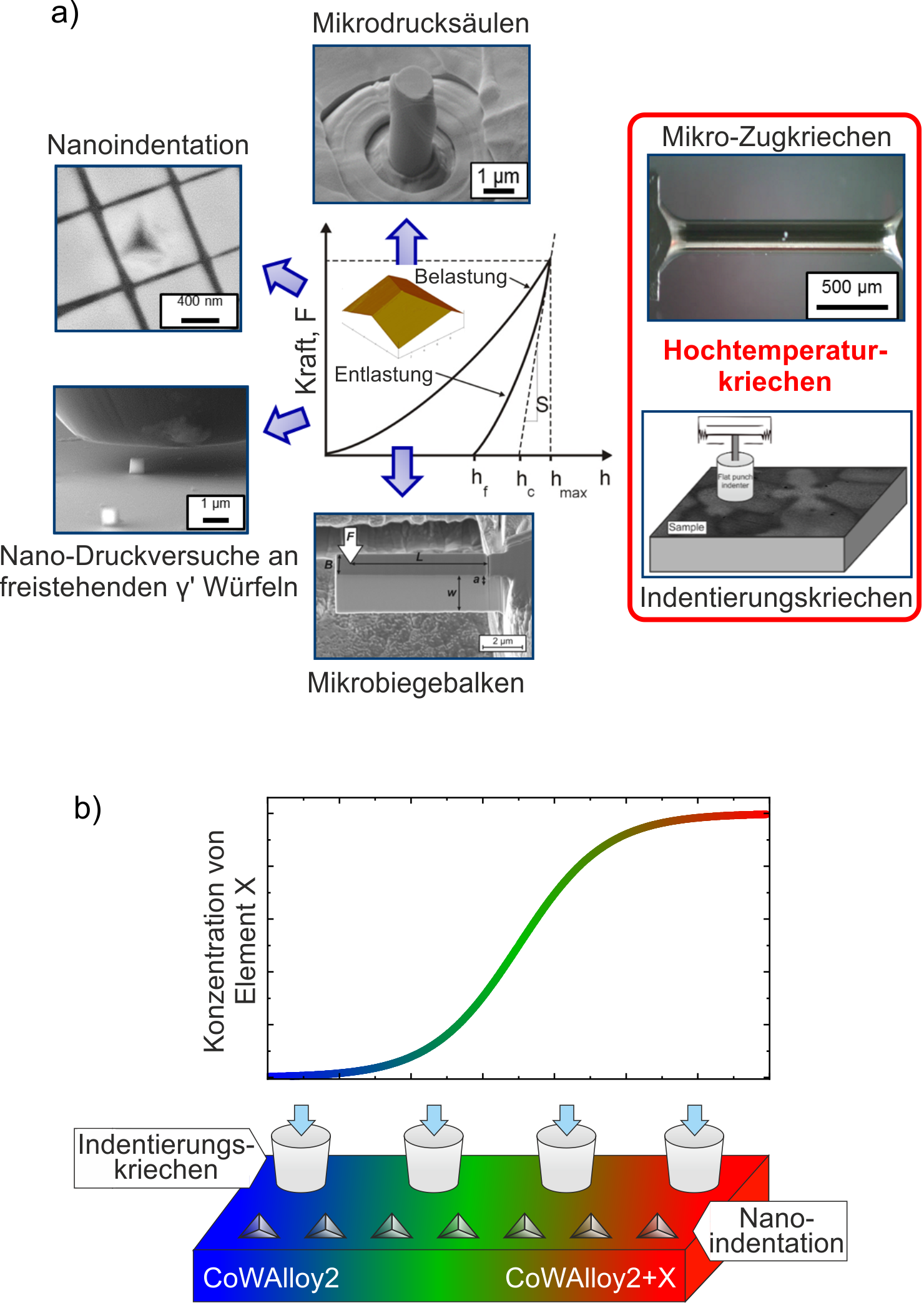

a) Micro- and nanomechanical testing techniques at WW1.

b) Schematic illustration of combinatorial investigations with nanoindentation and indentation creep experiments on diffusion couples.

The scientific objective of this project is to investigate the local mechanical properties of single crystalline Nickel- and Cobalt-base superalloys at ambient and elevated temperatures. Furthermore, the influence of hierarchical microstructures and different alloying elements on the strength of the γ and γ′ phase as well as the influence of local inhomogeneities are analyzed.

Moreover, using these methods and particularly micro indentation creep experiments, combinatorial investigations on diffusion couples are used to investigate the influence of different alloying elements on superalloys. A great advantage of these methods is the ability to characterize the microstructure and the mechanical properties of many different alloy compositions together at high temperatures on a single sample due to the present concentration gradient.

This project is part of the Collaborative Research Center SFB/Transregio 103 “From atoms to turbine blades – a scientific basis for a new generation of single crystal superalloys” as project A6. The SFB/TR 103 was extended for an additional funding period from January 2020 to December 2023. In this third funding period, the research activities in project A6 focus particularly on the investigation of:

- Local creep properties at elevated temperatures using microtensile and microindentation creep experiments (temperatures up to 800°C under compressive and 1100°C under tensile load)

- Fracture toughness of TCP phases and interfaces using microcantilever bending experiments

- Nano compression tests of freestanding γ′ cubes with detailed defect analysis