Polycrystalline High Entropy Superalloys (PHESA)

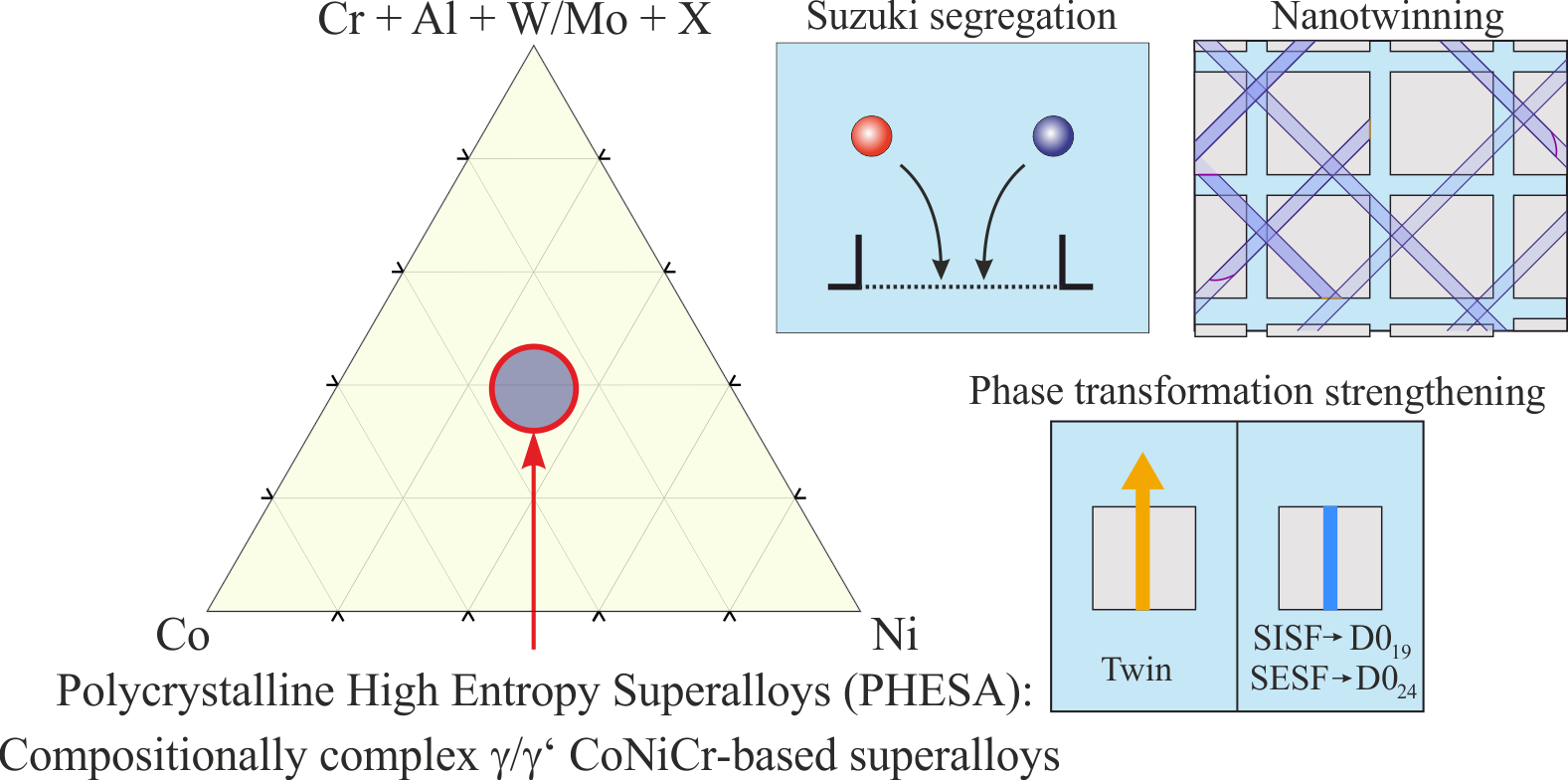

Polycrystalline High Entropy Superalloys (PHESA) – Combining novel strengthening mechanisms in compositionally complex CoNiCr-based superalloys with a large fraction of multicomponent intermetallic precipitates

Subject area:

High Temperature Materials

Responsible Employees:

Polycrystalline Ni-base superalloys are the material of choice for gas turbine discs in the turbine section as they are the only material system to simultaneously exhibit sufficient creep strength, ductility and corrosion resistance. The rediscovery of Co-base superalloys in 2006 sparked worldwide scientic interest in creating a new class of superalloys. In particular polycrystalline CoNi-base superalloys exhibit an excellent property profile and a high potential for application.

In these polycrystalline CoNi-base superalloys, a medium-entropy fcc g CoNiCr matrix alloyed with refractory elements is strengthened by multicomponent (Ni,Co,X)3(Al,W/Mo,Cr,X) g¢ precipitates, which is why they are also classified as complex concentrated alloys or high-entropy superalloys. One of their particularities are the low defect energies of the g and g’ phase in comparison with Ni-base superalloys, which lead to different deformation mechanisms. Additionally, these low defect energies enable the usage of new strengthening mechanisms, which are currently not employable in Ni-base superalloys.

In this project, which is embedded in the DFG-priority program SPP 2006: Alloys with a complex composition – high entropy alloys (CCA – HEA), two main topics will be adressed after a comprehensive characterization of the initial microstructure of the polycrystalline high entropy superalloys (PHESAs): (i) Investigation of the deformation mechanisms in polycrystalline high entropy superalloys under tensile load at different creep conditions and at constant strain rate experiments. (ii) Evaluation of the potential of unexplored strengthening mechanisms in this new alloy class, which can be employed due to the low stacking fault energy, i.e. the Suzuki mechanism, phase transformation strengthening and the effect of nanotwinned structures.