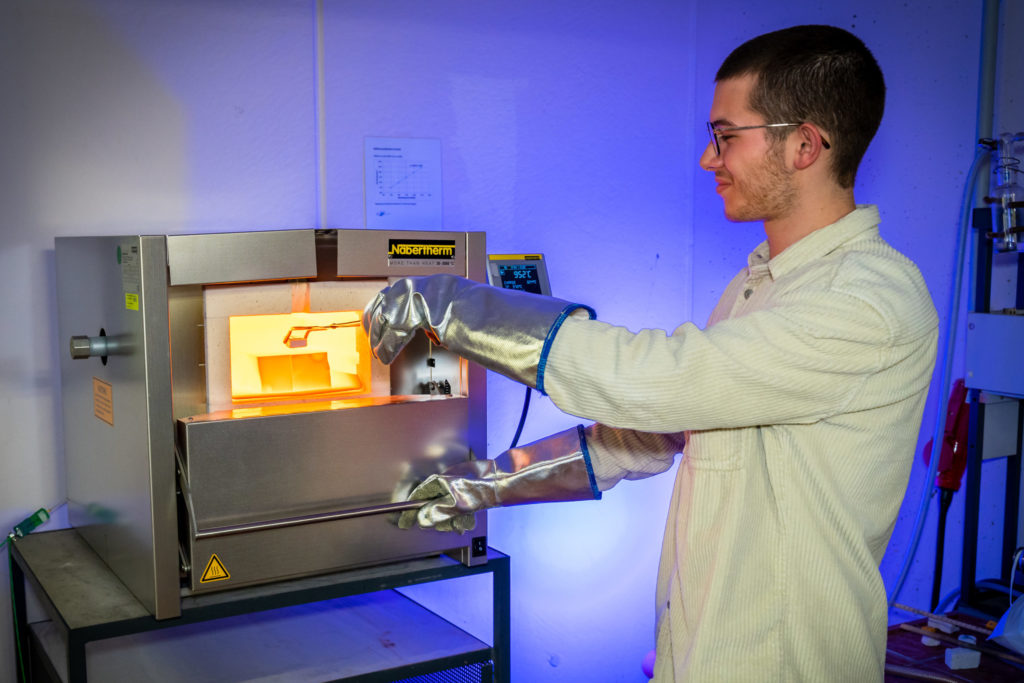

Heat treatments

Materials are often heat treated to specifically adjust the microstructure. Thus, the materials are optimized with regard to their application. Different furnaces up to temperatures of 1350°C are available at the institute WWI, using different atmospheres (vacuum, inert gas, forming gas) and cooling possibilities (compressed air, water quenching):

- (circulating air) chamber furnaces – up to 1600°C

- furnaces with argon atmosphere – up to 1450°C

- furnace with forming gas (Ar + 5 % H2) – up to 1500°C

- vacuum tube furnaces – up to 1500°C

- drying furnace (vacuum possible) – up to 250°C

- vertical furnace with possibility of fast quenching in water (argon atmosphere possible) – up to 1300°C

Responsible employees:

Rene Hagen

Department of Materials Science and Engineering

Chair of General Materials Properties

- Phone number: +49 9131 85-27481

- Email: rene.hagen@fau.de