During high-pressure hydrogen charging, the materials are exposed to a very high hydrogen pressure. This allows the molecular hydrogen to dissociate and be absorbed at the surface of the materials. Of particular note is that this method can be performed at elevated temperatures. This allows materials with low hydrogen diffusion coefficients to be effectively charged with hydrogen. Thus austenitic materials, which are often considered to be hydrogen resistant, can be effectively charged and investigated. Corrosion processes are eliminated with this method. Furthermore, charging with compressed hydrogen enables experiments to be carried out close to the application, since materials are often exposed to compressed hydrogen in their use.

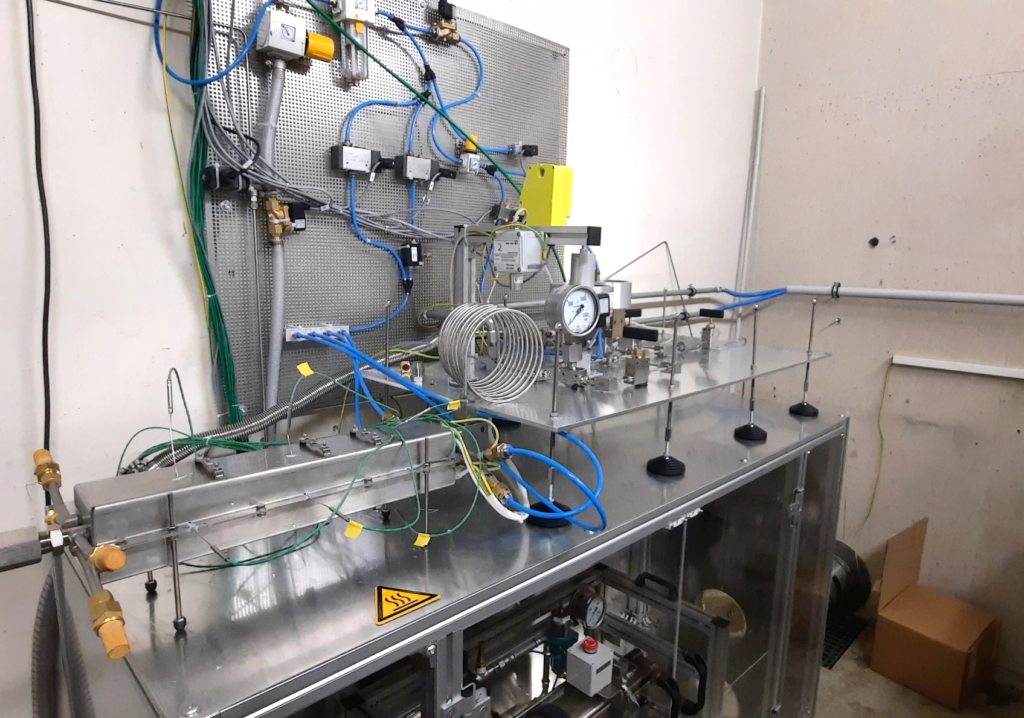

Due to the high safety requirements for handling high-pressure hydrogen, this process is only possible in specially secured laboratories. FAU has such a high-pressure laboratory. At the chair WWI a facility for high pressure hydrogen charging was developed and built. With this facility it is possible to expose materials to a maximum hydrogen pressure of 1000 bar (100 MPa) at a maximum temperature of 300 °C. Such a combination of pressure and temperature can only be achieved by a few experimental systems worldwide. Thus, an almost unique method for hydrogen charging is available at WWI. Samples up to a maximum diameter of 10 mm and a maximum length of 600 mm can be charged in the facility.

Responsible employees:

Jan-Oliver Hücking, M. Sc.

Department of Materials Science and Engineering

Chair of General Materials Properties

- Phone number: +49 9131 85-27481

- Email: jan-oliver.h.huecking@fau.de