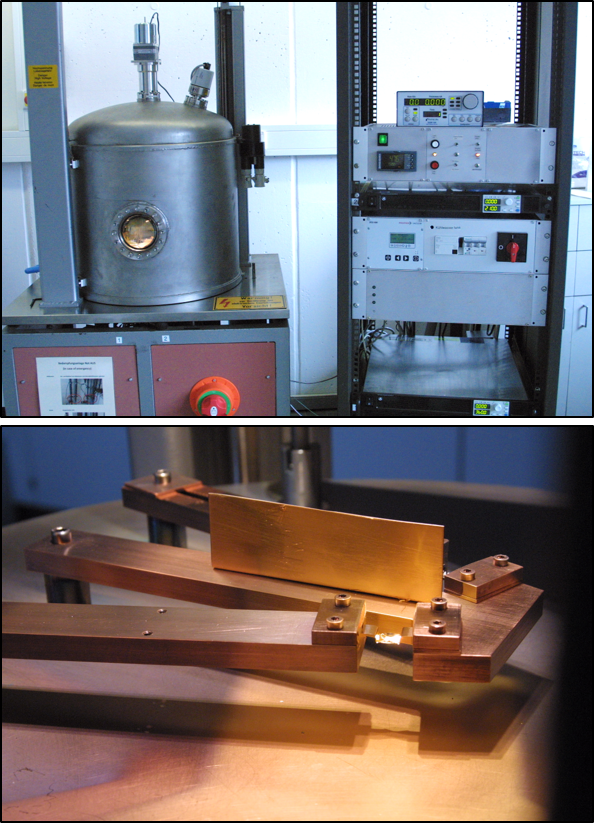

With the self-built evaporation unit called „EVU-MSE-1“ thin films can be deposited by physical vapour deposition. Two crucibles can be mounted between the copper electrodes with a maximum output of 210 A and 360 A, respectively. The deposition rate and the thickness are monitored by a quarz crystal microbalance. The substrate holder can rotate in two different speeds during the deposition to obtain a homogenious thickness in one run. Halogen lamps installed above the substrate holder control the substrate temperature and used to heat treat the samples directly after deposition without breaking the vacuum.

Responsible employees:

Department of Materials Science and EngineeringDr. mont. Michael Wurmshuber

Chair of General Materials Properties